If you want to improve the visual appearance of your home, retail business, or commercial facility, you have many options. When installing a ceiling, you could go with the routine choice of standard white acoustical panels.

However, if you want a more interesting look, you can choose Barn Tin Ceiling Tiles from Dakota Tin.

These unique tiles are not made like other products. As you’ll learn, they are made through an interesting yet simple process that creates world-class ceiling tile while also benefiting the environment...

Locating Salvageable Panels: The First Step

We obviously can’t create barn tin ceiling tiles without material, and for that we need high-quality tin that we can process at our facility. This means locating barns that are either being demolished or remodeled. We have relationships with people all over the midwest, so supplying whatever quantity of tin you need is possible. We are often informed about barns that are being torn down, giving us a chance to salvage the tin.

If we hear about someone who will be replacing the tin on their barn, or completely demolishing the existing structure, we ask permission to come by with our equipment and remove the tin. This not only allows us to gain material, it also keeps metal from reaching the landfill.

Choosing Only High-Quality, Reliable Panels

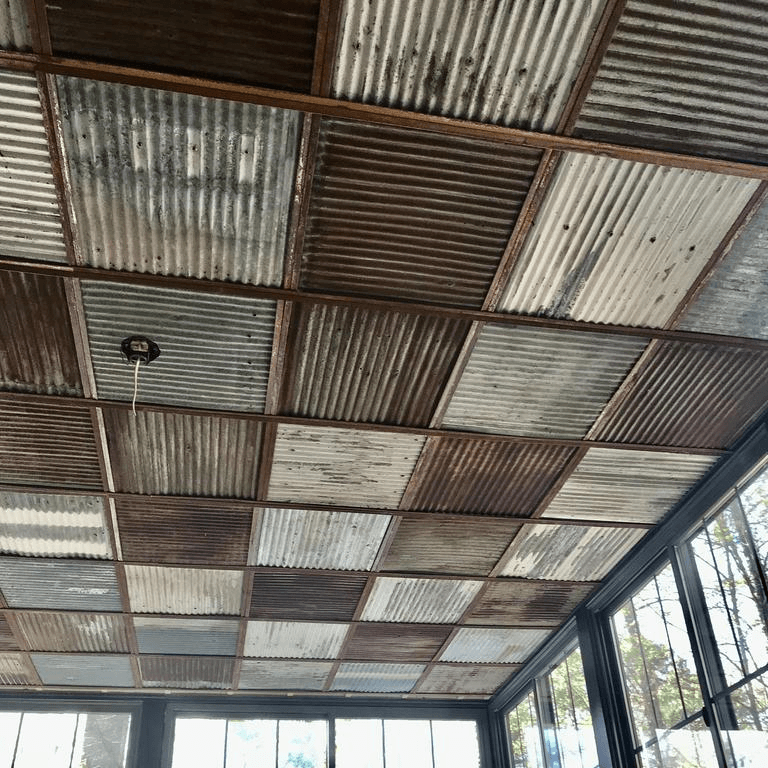

While we are passionate about keeping metal and other scraps out of the landfills and recycling system, we only select the finest materials for use as barn tin ceiling tiles. All the panels we bring to our facility must be 1.25-inch corrugated steel. This is the unofficial standard in barn tin of yesterday, and it fits with almost all ceiling grids, but there are panels out there that do not meet this requirement. However, this size is common among major panel manufacturers, so there are many panels that meet our needs.

Some panels, quite frankly, are too damaged to use as a barn tin ceiling tile. We can bend and straighten some, but if they are too damaged or dented, we cannot use them. We are extremely meticulous about the panels we choose, which results in the best tiles for your ceiling.

Removing the Panels

Removal of the panels is simple, but takes a bit of hard work. There are no special tools, just a pair of gloves, a flat bar, and a ladder if needed. It usually takes few hours to remove the panels we need, but if the barn is particularly large it may take a day or two. Above all, safety is an important concern when salvaging panels.

When the panels are back at our shop, we simply use our custom equipment to cut them into 2’x2’ pieces. There is no special coloring or seals, and the unique nature of each individual tile is maintained. By keeping the rustic appearance with simple processing, we are able to create panels that look great in homes, retail outlets, restaurants, and more.

Fill Your Space with DakotaTin Tiles

You can have a gorgeous appearance for your home, office, or commercial area by ordering Barn Tin Ceiling Tiles from DakotaTin.

Contact us today to learn more about these and other decorative and rustic products.